Customizable Insulated Heating Wire Made from CuNi10 NC015 Alloy FEP Insulation High Temperature Resistance

Categories:

Insulated Heating Wire

Categories:

Customizable Insulated Heating Wire Made from CuNi10 NC015 Alloy FEP Insulation High Temperature Resistance

PRODUCT CENTER

Product Description

Customizable Insulated Heating Wire Made from CuNi10 NC015 Alloy and FEP Insulation for High Temperature Resistance

CuNi10 NC015 alloy material insulated FEP heating wire is a high-performance heating element known for its durability and stability. Comprising 90% copper and 10% nickel, the CuNi10 alloy offers excellent electrical resistance, corrosion resistance, and temperature stability. The wire is insulated with FEP (Fluorinated Ethylene Propylene), providing superior thermal resistance, chemical resistance, and electrical insulation. This combination makes it ideal for applications in heating systems, sensors, and industrial equipment. The FEP insulation ensures long service life and consistent performance in harsh environments. CuNi10 NC015 heating wire is widely used in aerospace, automotive, and electronics industries, offering reliable heat generation with minimal energy loss.

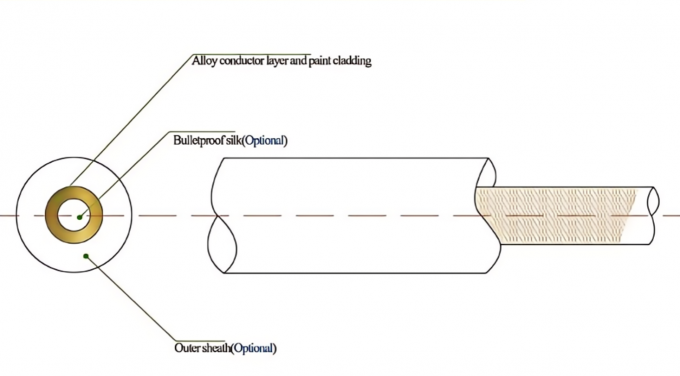

Bulletproof Silk (Optional)

|

Material |

Temperature resistance |

Thermal decomposition |

Applied for grade |

Advantages |

|

High strength aramid |

In a 100 to 250 ℃ long-term use will not have obvious change and impairment |

Thermal decomposition temperature more than 450 degrees |

Applied for more than 110N |

1. Good mechanical 2. Heat resistant and flame retardant 3. The stable chemical properties 4. Radiation resistanc 5. Durability |

Alloy Material

|

Texture |

Ni-Cu (Can be enameled) |

|

Resistance |

According to the requests |

|

Wire diameter |

0.05~0.12mm |

|

Characteristic |

1. High strength 2. Strong hardness 3. Anti-corrosion 4.Thermoelectricity good |

|

Operating principle |

Heating filament dogan twisted |

Paint Cladding(Optional)

|

Texture |

Polyurethane |

Polyetherimide |

|

Temperature class |

-50~150℃ |

-160~180℃ |

|

Characteristic |

1. Performance wide adjustable range well-adapted 2. Adhesive performance is good 3. Good elasticity, good resilien, can be used for dynamic joint 4. Good flexibility at low temperatures 5. Good weather resistance,service life up to 15~20 years 6. Good oil resistance 7. Biological aging resistance 8. Moderate cost |

1. Excellent Mechanical Properties 2. Good electrical insulatingperformance 3. Excellent radiation resistance 4. Excellent resistanceto high and low temperature performance 5. Excellent wear resistance 6. Excellent microwave through performance 7. Strong plastcity |

Outer Sheath (Optional)

|

Texture |

PA12 |

TPEE |

PVC |

FEP |

|

Plastic outer diameter |

0.8mm~1.0mm |

|||

|

Temperature class |

-40~140C |

-70~200℃ |

-30~125℃ |

-100~220℃ |

|

Dielectric strength |

39Kv/mm |

36Kv/mm |

36Kv/mm |

42Ky/mm |

|

Dielectric constant |

1.9×10^7 HZ |

1.4×10^7 HZ |

1.4×10^7 HZ |

2.8×10 HZ |

|

Breaking strength |

19~25MPa |

18~24MPa |

18~24MPa |

15~22MPa |

Key Features of CuNi10 NC015 Alloy Material Insulated FEP Heating Wire

1. Conductor Material:

CuNi10 NC015 Alloy (Copper-Nickel Alloy with 10% Nickel content)

High electrical resistivity and corrosion resistance

Excellent mechanical stability under high temperatures

2. Insulation Material:

FEP (Fluorinated Ethylene Propylene)

High-temperature resistance (up to 200°C continuous operation)

Excellent chemical resistance

Non-flammable and self-extinguishing

Good electrical insulation properties

3. Temperature Resistance:

Suitable for high-temperature applications due to both CuNi10 alloy and FEP insulation

Long lifespan in extreme temperature environments

4. Electrical Properties:

Stable resistance over a wide range of temperatures

Low noise and interference

Ideal for precision heating applications

5. Flexibility & Durability:

Flexible and lightweight design

Resistant to bending and mechanical stress

Excellent for applications requiring repeated movements

6. Corrosion Resistance:

High resistance to oxidation and corrosion, especially in humid or chemical-rich environments

7. Safety & Certification:

RoHS compliant

Non-toxic insulation materials

This combination makes CuNi10 NC015 FEP heating wires ideal for demanding applications requiring precision, durability, and resistance to harsh environments.

Applications

The CuNi NC015 alloy material insulated FEP heating wire is commonly used in various applications due to its excellent electrical, thermal, and corrosion-resistant properties. Here are the primary applications of this heating wire:

1. Industrial Heating Systems

Surface Heating Elements: Used in heaters for pipes, tanks, and vessels.

Heat Tracing Systems: To prevent freezing of liquids in pipes or maintain process temperatures.

Hot Plate and Pad Heaters: For industrial equipment that requires consistent heating.

2. Aerospace and Automotive

De-icing Systems: Installed on aircraft wings or vehicle windshields.

Battery Heating Systems: To maintain optimal battery temperature in electric vehicles.

3. Medical Devices

Medical Instrument Heating: Such as heating elements in diagnostic and laboratory equipment.

Surgical Instrument Warming: Prevents condensation or ensures operational temperature.

4. Consumer Electronics

Heated Mattress Pads or Blankets

Underfloor Heating Systems

Anti-Condensation Heating in Appliances: For refrigerators, cameras, or display systems.

5. Scientific Research Equipment

Temperature-Controlled Environments

Laboratory Test Chambers

6. Chemical and Food Processing

Liquid Heating Systems: In chemical processing lines.

Food Warmer Units

7. Marine Applications

Anti-Icing Systems for Ship Equipment

Pipeline Heating

Why CuNi NC015 Alloy?

High corrosion resistance

Excellent electrical resistivity

Stable resistance at elevated temperatures

Long lifespan in harsh environments

Why FEP Insulation?

High-temperature resistance (up to 200°C)

Non-stick and chemical-resistant surface

Excellent dielectric properties

Flexible and durable

This combination makes the CuNi NC015 alloy insulated with FEP an ideal heating wire solution for precision, durability, and safety in various demanding applications.

WHY CHOOSE US

OEM/ODM

We provide OEM/ODM service and customized service.

COMPETITIVE PRICE

We can give customers the most competitive price to meet your budget and guarantee the quality.

CERTIFICATION

We have the authority certificates of quality and safety which are all in accordance with international quality standards.

R&D TEAM

Our R&D team can help make our products work better for your project.

FACTORY APPEARANCE

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

Factory

Factory

Factory

Factory

Factory

Factory

PACKAGING AND DELIVERY

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

FAQ

Can I visit your factory before ordering?

Do you provide samples?

What are the advantages of price and quality?

Can you supply what is the service?

Are you Manufacture or Trade Company?

RELATED PRODUCTS

GET A QUOTE

Leave your contact information and get a free product quote