19 Strands Pure Nickel Alloy Wire CX1201 For Heating Cable And Car Seat

Categories:

Alloy Wire Strand

Categories:

19 Strands Pure Nickel Alloy Wire CX1201 For Heating Cable And Car Seat

PRODUCT CENTER

Product Description

19 Strands Heating Pure Nickel Wire Alloy For Heating Cable And Heating Wire Car Seat

Strands Alloy Nickel Chrome Wire is a specialized material known for its high resistance to corrosion, heat, and oxidation, making it ideal for applications in extreme environments. Composed of a mix of nickel and chromium, this alloy wire can withstand high temperatures, typically up to 1,200°C (2,192°F), which is critical in industries requiring consistent performance under thermal stress, such as aerospace, automotive, and power generation.

Nickel-chrome wires are also highly resistant to oxidation, meaning they maintain their integrity and resist surface degradation when exposed to air at high temperatures. This stability is essential for heating elements, thermocouples, and resistance heating, where prolonged exposure to heat would otherwise degrade performance.

Additionally, the alloy’s flexibility and ductility allow it to be manufactured into various wire gauges and stranded configurations. Its mechanical properties also enable good weldability and workability, which are advantageous in custom fabrication and repairs. In summary, Strands Alloy Nickel Chrome Wire offers durability, thermal stability, and versatility, making it a preferred choice for high-performance industrial applications.

Common specifications:

| Prouuct code | Description | Standard packing | Specification |

| CX1201 | 19-Strand Nickel Chrome Wire (80/20) | 500m/roll | Materials:80%Nickel& 20%chromium Overal Diameter 2.83mm No of Strands:19strands 19/0.56mm,twisted together |

Available in any of the following alloys:

Range:

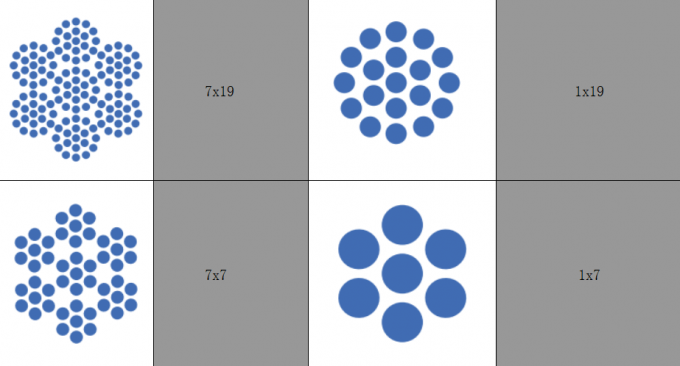

| 7 x 19 | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 7x7 | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 1x19 | 0.07mm (.0028”) to 0.71mm (0.028”) |

| 1x7 | 0.06mm (.0024”) to 0.71mm (0.028”) |

Some key features include:

1.High Electrical Resistivity: NiCr wire has a high electrical resistivity, which makes it suitable for use as a heating element in various devices.

2.Excellent Oxidation Resistance: It can withstand high temperatures without significant oxidation, making it durable for use in furnaces and other high-temperature environments.

3.Thermal Stability: NiCr wire maintains its properties over a wide range of temperatures, ensuring consistent performance.

4.Low Thermal Expansion: It has a low coefficient of thermal expansion, which means it doesn't expand or contract much with temperature changes, providing dimensional stability.

5.High Melting Point: With a high melting point, NiCr wire can be used in applications where other materials would fail due to heat.

6.Corrosion Resistance: NiCr wire is resistant to corrosion, which is beneficial in environments where it may be exposed to moisture or chemicals.

7.Strength and Ductility: It is strong and ductile, allowing it to be formed into various shapes without breaking.

8.Uniform Heating: When used as a heating element, NiCr wire provides uniform heat distribution.

9.Long Service Life: Due to its durability and resistance to wear, NiCr wire has a long service life in demanding applications.

10.Easy to Weld: NiCr wire can be easily welded, which is advantageous for manufacturing and repair processes.

11.Non-Magnetic: It is non-magnetic, which can be an important feature in applications where magnetic interference is undesirable.

These features make stranded nickel-chrome wire an ideal material for applications such as heating elements in ovens, furnaces, toasters, hair dryers, and other appliances, as well as in the manufacturing of electronic components and in the aerospace industry for high-temperature applications.

Applications:

Heating Elements:

This wire is a preferred choice for heating elements in appliances like hair dryers, toasters, and ovens. It's also used in industrial furnaces for melting metals and other materials.

Laboratories:

In laboratory settings, it's utilized in equipment such as heating coils and hot plates.

Construction:

The wire finds use in construction for applications like rope heaters and heating cables.

Specialized Electronics:

It's employed in specialized electronics, including glassblowing and ceramic sculpture equipment.

Aerospace:

NiCr-based metal matrix composites, which can include Cr20Ni80, are used in the aerospace industry for their enhanced hardness and strength, particularly in components produced by selective laser melting processes.

Thermocouples:

Although not specifically mentioned for Cr20Ni80, nickel-chrome alloys are generally used in thermocouples for temperature measurement in various industries.

Industrial Heating:

Cr20Ni80 wire is widely used in electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical, and defense industries.

Resistors:

It's used in electrical circuits for resistance heating and temperature control.

Appliance Heating:

Found in household appliances like soldering irons and other heating devices.

These applications leverage the high-temperature stability, oxidation resistance, and electrical resistivity of stranded nickel-chrome wire, making it a versatile material for both everyday and industrial use.

WHY CHOOSE US

OEM/ODM

We provide OEM/ODM service and customized service.

COMPETITIVE PRICE

We can give customers the most competitive price to meet your budget and guarantee the quality.

CERTIFICATION

We have the authority certificates of quality and safety which are all in accordance with international quality standards.

R&D TEAM

Our R&D team can help make our products work better for your project.

FACTORY APPEARANCE

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

Factory

Factory

Factory

Factory

Factory

Factory

PACKAGING AND DELIVERY

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

FAQ

Can I visit your factory before ordering?

Do you provide samples?

What are the advantages of price and quality?

Can you supply what is the service?

Are you Manufacture or Trade Company?

RELATED PRODUCTS

GET A QUOTE

Leave your contact information and get a free product quote