CX1201 The Durable and Flexible Alloy Wire Strand for Household Heaters and Electric Pipes

Categories:

Alloy Wire Strand

Categories:

CX1201 The Durable and Flexible Alloy Wire Strand for Household Heaters and Electric Pipes

PRODUCT CENTER

Product Description

CX1201 The Durable and Flexible Alloy Wire Strand for Household Heaters and Electric Pipes

19-Strand Nickel-Chrome Wire refers to a specific type of wire made from a combination of Nickel (Ni) and Chromium (Cr), designed for various high-performance applications. The "19-strand" designation indicates that the wire is made up of 19 individual strands, which are twisted or braided together to form a single wire.

19-Strand Nickel-Chrome Wire is a high-performance material used primarily for its resistive heating capabilities in various industrial and household applications. The combination of high electrical resistivity, thermal stability, corrosion resistance, and flexibility makes it ideal for environments that demand reliable, long-lasting performance at high temperatures.

Common specifications:

| Prouuct code | Description | Standard packing | Specification |

| CX1201 | 19-Strand Nickel Chrome Wire (80/20) | 500m/rol | Materials:80%Nickel& 20%chromium Overal Diameter 2.83mm No of Strands:19strands 19/0.56mm,twisted together |

Available in any of the following alloys:

Range:

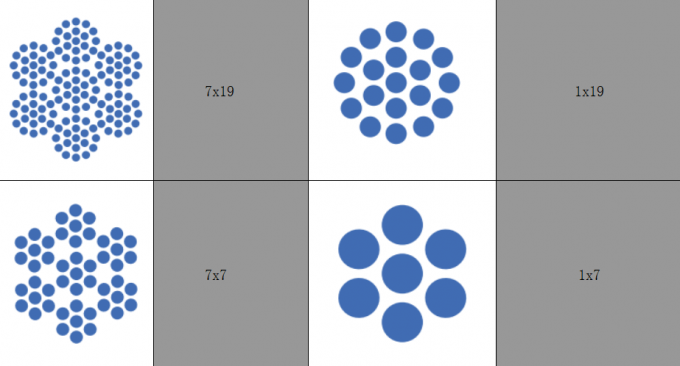

| 7 x 19 Strands | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 7x7 Strands | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 1x19 Strands | 0.07mm (.0028”) to 0.71mm (0.028”) |

| 1x7 Strands | 0.06mm (.0024”) to 0.71mm (0.028”) |

Some key features of 19 Strands Alloy Nickel Chrome Wire include:

Composition:

Typically consists of around 80% Nickel (Ni) and 20% Chromium (Cr), though the exact composition can vary depending on the specific alloy used (such as NiCr 80/20, or other similar variants).

Nickel offers excellent resistance to oxidation, corrosion, and high-temperature environments.

Chromium enhances the alloy's resistance to high temperatures and improves the material's durability and tensile strength.

Electrical Properties:

High Resistivity: The wire has a relatively high electrical resistivity, which is why it is commonly used in heating elements (e.g., electric ovens, toasters, industrial furnaces) where it is heated by electrical current.

Stable Resistance: The resistance of Nickel-Chrome alloys remains stable over a wide temperature range, making them ideal for use in resistive heating applications.

Mechanical Properties:

Good Tensile Strength: The 19-strand configuration gives the wire higher flexibility and strength compared to single-strand wire, making it durable and resistant to mechanical stresses.

Enhanced Flexibility: The multiple strands in the wire improve its flexibility, which is beneficial when the wire needs to be coiled, bent, or twisted in different applications.

Thermal Stability:

The alloy maintains its structural integrity and resistance properties at elevated temperatures, often exceeding 1000°C (1832°F), depending on the specific alloy variant.

It is widely used in high-temperature environments where other materials would degrade.

Corrosion Resistance:

Nickel-chromium alloys are resistant to oxidation, corrosion, and scaling at high temperatures, making them suitable for long-term use in harsh environments.

Applications:

Heating Elements:

Used in electric heaters, furnaces, toasters, and heat guns due to its ability to generate heat efficiently when an electrical current is passed through it.

Resistive Components:

Employed in precision resistors, where stable and consistent resistance is needed.

Often used in shunt resistors for current sensing applications.

Industrial and Laboratory Heating:

Used in industrial equipment, laboratory heating coils, and other devices where precise temperature control and high heat resistance are required.

Thermocouples:

Occasionally used as part of the thermocouple wire for high-temperature measurements, though other alloys like Platinum are more commonly used for thermocouples.

Aerospace and Automotive:

Due to its high strength, corrosion resistance, and thermal stability, it is also found in certain aerospace and automotive applications requiring high-performance materials.

Advantages of 19-Strand Nickel-Chrome Wire:

Increased Durability: The multi-strand design reduces the likelihood of breakage under mechanical stress.

Higher Flexibility: The wire can be coiled or shaped more easily than a single-strand wire of the same material.

Consistent Performance: The combination of nickel and chromium ensures that the wire performs consistently across a broad range of temperatures and environments.

Corrosion and Oxidation Resistance: The high levels of nickel and chromium ensure longevity, even in harsh or corrosive environments.

WHY CHOOSE US

OEM/ODM

We provide OEM/ODM service and customized service.

COMPETITIVE PRICE

We can give customers the most competitive price to meet your budget and guarantee the quality.

CERTIFICATION

We have the authority certificates of quality and safety which are all in accordance with international quality standards.

R&D TEAM

Our R&D team can help make our products work better for your project.

FACTORY APPEARANCE

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

Factory

Factory

Factory

Factory

Factory

Factory

PACKAGING AND DELIVERY

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

FAQ

Can I visit your factory before ordering?

Do you provide samples?

What are the advantages of price and quality?

Can you supply what is the service?

Are you Manufacture or Trade Company?

RELATED PRODUCTS

GET A QUOTE

Leave your contact information and get a free product quote