CX1207 Strands Pure Nickel Alloy Wire for electric heating elements and industrial furnaces

Categories:

Alloy Wire Strand

Categories:

CX1207 Strands Pure Nickel Alloy Wire for electric heating elements and industrial furnaces

PRODUCT CENTER

Product Description

CX1207 Strands Pure Nickel Alloy Wire for electric heating elements and industrial furnaces

Strands Alloy Pure Nickel Cold Tail Wire is a high-quality wire made from pure nickel, designed for applications that require exceptional corrosion resistance, high conductivity, and excellent mechanical properties. Pure nickel is known for its resistance to a wide range of corrosive environments, including acidic and alkaline conditions, making it ideal for industries such as chemical processing, electronics, and marine environments.

This wire is typically used in situations where strength, flexibility, and resistance to oxidation are essential. Its cold tail design refers to the wire being formed without the use of heat, maintaining the material’s integrity and ensuring high-quality performance. Pure nickel’s excellent ductility allows for easy manipulation and shaping without sacrificing strength, which makes it suitable for precision applications, such as in electrical connectors, battery components, and high-performance cables.

The wire’s resistance to high temperatures and its ability to handle thermal stresses make it valuable in demanding environments where high thermal conductivity is required. It also maintains good workability, allowing for intricate designs and use in fine applications. In summary, Strands Alloy Pure Nickel Cold Tail Wire offers a combination of durability, corrosion resistance, and versatility, making it an ideal choice for high-performance and demanding industrial applications.

Common specifications:

| Prouuct code | Description | Standard packing | Specification |

| CX1207 | Nickel Cold Tail Wire | 500m/roll | Materials:Pure Nickel Overal Diameter 3.07mm No of Strands: 18/0.61mm+1/0.71mm,twisted togethe |

Available in any of the following alloys:

Range:

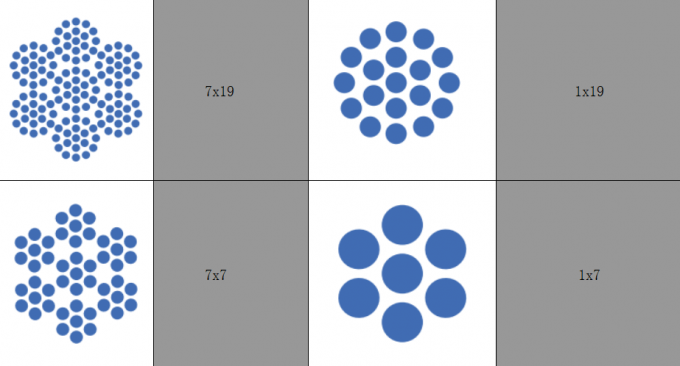

| 7 x 19 | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 7x7 | 0.08mm (.0031”) to 0.71mm (0.028”) |

| 1x19 | 0.07mm (.0028”) to 0.71mm (0.028”) |

| 1x7 | 0.06mm (.0024”) to 0.71mm (0.028” |

Some key features include:

1.High Corrosion Resistance: Pure nickel offers exceptional resistance to corrosion in harsh environments, including exposure to acids, alkalis, and saltwater. This makes it suitable for use in chemical processing, marine, and industrial applications.

2.Excellent Electrical Conductivity: The wire maintains good electrical conductivity, making it ideal for use in electrical components such as connectors, conductors, and battery applications.

3.Thermal Stability: Pure nickel can withstand high temperatures, maintaining its structural integrity and performance in environments where heat resistance is crucial.

4.High Ductility and Flexibility: The wire is highly ductile, allowing it to be easily formed, bent, or twisted without breaking, making it versatile for a range of manufacturing processes and custom applications.

5.Cold Tail Design: The cold tail manufacturing process ensures that the wire retains its high-quality characteristics without the application of heat, preserving its strength, conductivity, and corrosion resistance.

6.Mechanical Strength: While being flexible, the wire still offers good tensile strength, making it suitable for mechanical applications where durability is required.

7.Weldability: Pure nickel can be easily welded, which is beneficial for assembling or connecting components in various applications.

8.Versatility: Due to its combination of properties, the wire can be used across a broad range of industries, including electronics, aerospace, and energy sectors.

Applications:

Electrical and Electronics Industry

Conductors and Connectors: Used in wiring, connectors, and terminals due to its excellent conductivity and resistance to corrosion.

Battery Components: Utilized in battery connections and electrodes, particularly in lithium-ion and other rechargeable batteries where stability and reliability are critical.

Heat-Resistant Applications

Heating Elements: Employed in heating elements for high-temperature applications like electric furnaces and industrial heating systems.

Thermocouples: Used in temperature sensors for monitoring heat in industrial processes, providing reliable performance in high-temperature environments.

Chemical and Petrochemical Industries

Corrosion-Resistant Parts: Used in environments where exposure to acids, alkalis, and other corrosive substances is common. Components such as pumps, valves, and fittings are often made from pure nickel wire.

Chemical Reactors: Applied in reactor components and other parts exposed to corrosive chemicals.

Aerospace and Automotive Sectors

Engine Components: The wire is used in high-performance applications such as engine parts, due to its heat resistance and durability.

Wiring Systems: In aerospace wiring systems, where both heat resistance and corrosion resistance are necessary.

Marine Applications

Saltwater Resistance: Perfect for use in marine environments, where its resistance to saltwater corrosion makes it ideal for components like marine cables and electronic systems.

Custom Fabrication and Fine Applications

Precision Components: Ideal for intricate, small-scale custom wire applications in specialized machinery, scientific instruments, and telecommunications.

Welding:

Welding Electrodes: Its good weldability makes it useful in various welding processes, where nickel-based electrodes or filler materials are required.

These applications demonstrate how Strands Alloy Pure Nickel Cold Tail Wire is versatile and essential in industries that demand reliability, strength, and long-term performance in challenging conditions.

WHY CHOOSE US

OEM/ODM

We provide OEM/ODM service and customized service.

COMPETITIVE PRICE

We can give customers the most competitive price to meet your budget and guarantee the quality.

CERTIFICATION

We have the authority certificates of quality and safety which are all in accordance with international quality standards.

R&D TEAM

Our R&D team can help make our products work better for your project.

FACTORY APPEARANCE

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

Factory

Factory

Factory

Factory

Factory

Factory

PACKAGING AND DELIVERY

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

FAQ

Can I visit your factory before ordering?

Do you provide samples?

What are the advantages of price and quality?

Can you supply what is the service?

Are you Manufacture or Trade Company?

RELATED PRODUCTS

GET A QUOTE

Leave your contact information and get a free product quote