Nickel-chromium-based Alloy Inconel Wire Mesh With Exceptional Strength For Critical Engineering Projects

Categories:

Alloy Mesh

Categories:

Nickel-chromium-based Alloy Inconel Wire Mesh With Exceptional Strength For Critical Engineering Projects

PRODUCT CENTER

Product Description

Inconel Wire Mesh Nickel-chromium-based Alloy Mesh With Exceptional Strength For Critical Engineering Projects

Inconel wire mesh is a high-performance, nickel-chromium-based alloy mesh known for its exceptional strength, corrosion resistance, and stability at elevated temperatures. It is widely used in demanding industrial applications where conventional materials fail. With excellent resistance to oxidation, carburization, and thermal fatigue, Inconel wire mesh ensures long-term performance in extreme environments. Its versatility extends to aerospace, chemical processing, marine, and energy sectors, where it is employed in filtration, separation, and thermal management systems. Available in various mesh sizes and wire diameters, Inconel wire mesh offers superior durability, consistent mechanical properties, and reliable protection against harsh chemicals and high-temperature gases. It is a reliable choice for critical engineering projects requiring robust materials.

Definition:

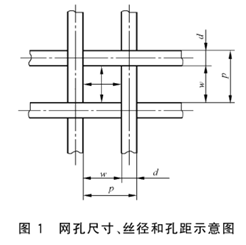

Mesh count

The number of hole spacing per 25.4mm length along the direction of the hole spacing

Mesh Size- w

Distance between adjacent longitude and latitude wire

Wire diameter- d

The diameter of the wire in the nickel net

Pitch-row p

Distance between centerline of two adjacent wire.

Weaving Type

The way in which the longitude and latitude are interwoven with each other, the nickle network is a square hole network, including plain weave and twill weave two ways

Technical data:

1 Technical requirements for weaved nickel mesh

1.1 Technical requirements for nickel wire

a. Chemical composition Nickel content >99.5%.

b. Diameter tolerance of nickel wire ±0.005mm

c. Nickel wire tensile strength >400Mpa, elongation >25%

1.2 Mesh size and mesh uniformity of nickel mesh conform to GB/T 17492

1.3 The allowable number of major defects of nickel mesh (holes, cracks, half weft, thin and dense channels, skip wire, loose weft/warp wire, warp loose channels) zero defect.

1.4 The maximum deviation of the overall size of the nickel mesh is ±0.5%

1.5 The flatness of the nickel mesh is less than 5mm/2.5m

Dimensions and tolerance

|

Dimensions |

≥0.03-0.1 |

≥0.1-0.3 |

≥0.3-0.6 |

≥0.6-1.0 |

≥1.0-3.0 |

≥3.0-6.0 |

|

Tolerance |

±0.002 |

±0.002 |

±0.005 |

±0.007 |

±0.008 |

±0.02 |

Key Features of Inconel Wire Mesh

Excellent High-Temperature Resistance

Withstands temperatures up to 1100°C (2012°F), making it ideal for applications in heat treatment, aerospace, and chemical processing.

Outstanding Corrosion Resistance

Highly resistant to oxidation, carburization, and chloride-induced stress corrosion cracking, even in harsh environments.

High Strength and Durability

Maintains mechanical integrity under thermal cycling and high-stress conditions.

Non-Magnetic Properties

Suitable for use in sensitive electronic and magnetic applications.

Good Fabricability

Easily woven, sintered, or formed into various mesh sizes and shapes.

Versatile Applications

Widely used in filtration, heating elements, catalyst support, and gas diffusion processes.

Customizable Mesh Sizes

Available in a wide range of wire diameters and mesh openings to meet specific requirements.

Low Thermal Expansion

Excellent dimensional stability even at high temperatures.

Chemical Compatibility

Compatible with a broad range of acids, alkalis, and organic compounds.

Inconel Wire Mesh Applications

Inconel wire mesh is widely recognized for its excellent high-temperature strength, corrosion resistance, and mechanical stability. It is commonly manufactured from high-performance nickel-chromium alloys such as Inconel 600, 601, 625, and 718. Its unique combination of properties makes it ideal for a range of demanding industrial and commercial applications:

Aerospace Industry

Used in gas turbine engines for filtration and shielding components, where resistance to oxidation and thermal cycling is critical.

Chemical Processing

Ideal for catalyst support grids, reactor internals, and filtration in aggressive chemical environments due to its exceptional corrosion resistance.

Heat Treatment

Functions as trays, baskets, and supports in high-temperature furnaces, maintaining structural integrity in oxidizing and carburizing atmospheres.

Petrochemical Industry

Utilized for demisters, separation screens, and mist eliminators in oil refineries and gas processing plants.

Marine and Offshore Applications

Resists seawater corrosion and biofouling, making it suitable for filters and protective screens in marine environments.

Nuclear Industry

Applied in fuel element spacers, reactor components, and support structures due to its strength and radiation resistance.

Electronics and Electrical Equipment

Used for electromagnetic shielding and grounding where high conductivity and stability at elevated temperatures are required.

|

Inconel wire mesh |

||

|

Mesh |

Wire Dia. (mm) |

Aperture (mm) |

|

2 |

1.80 |

10.90 |

|

3 |

1.60 |

6.866 |

|

4 |

1.20 |

5.15 |

|

5 |

0.91 |

4.17 |

|

6 |

0.80 |

3.433 |

|

8 |

0.60 |

2.575 |

|

10 |

0.55 |

1.990 |

|

12 |

0.50 |

1.616 |

|

14 |

0.45 |

1.362 |

|

16 |

0.40 |

1.188 |

|

18 |

0.35 |

1.060 |

|

20 |

0.30 |

0.970 |

|

26 |

0.28 |

0.696 |

|

30 |

0.25 |

0.596 |

|

40 |

0.21 |

0.425 |

|

50 |

0.19 |

0.318 |

|

60 |

0.15 |

0.273 |

WHY CHOOSE US

OEM/ODM

We provide OEM/ODM service and customized service.

COMPETITIVE PRICE

We can give customers the most competitive price to meet your budget and guarantee the quality.

CERTIFICATION

We have the authority certificates of quality and safety which are all in accordance with international quality standards.

R&D TEAM

Our R&D team can help make our products work better for your project.

FACTORY APPEARANCE

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

Factory

Factory

Factory

Factory

Factory

Factory

PACKAGING AND DELIVERY

With a professional technical team, we can provide personalized customization services according to customer project requirements, from product design, material selection to production process adjustment, to ensure that customers' special specifications and performance requirements are met.

FAQ

Can I visit your factory before ordering?

Do you provide samples?

What are the advantages of price and quality?

Can you supply what is the service?

Are you Manufacture or Trade Company?

RELATED PRODUCTS

GET A QUOTE

Leave your contact information and get a free product quote